Previous approaches toward stereoselective vinyl ether polymerizations have exclusively relied on chain end control to dictate facial addition to the propagating oxocarbenium ion which has provided access to isotactic pves in specific cases but is not general to alkyl vinyl ether monomers as a class 13 19.

Vinyl ether monomers.

However radical curable monomers have disadvantages such as 1 inhibition of polymerization by oxygen 2 the large volume shrinkage.

Advanced green syntheses of vinyl ether monomers.

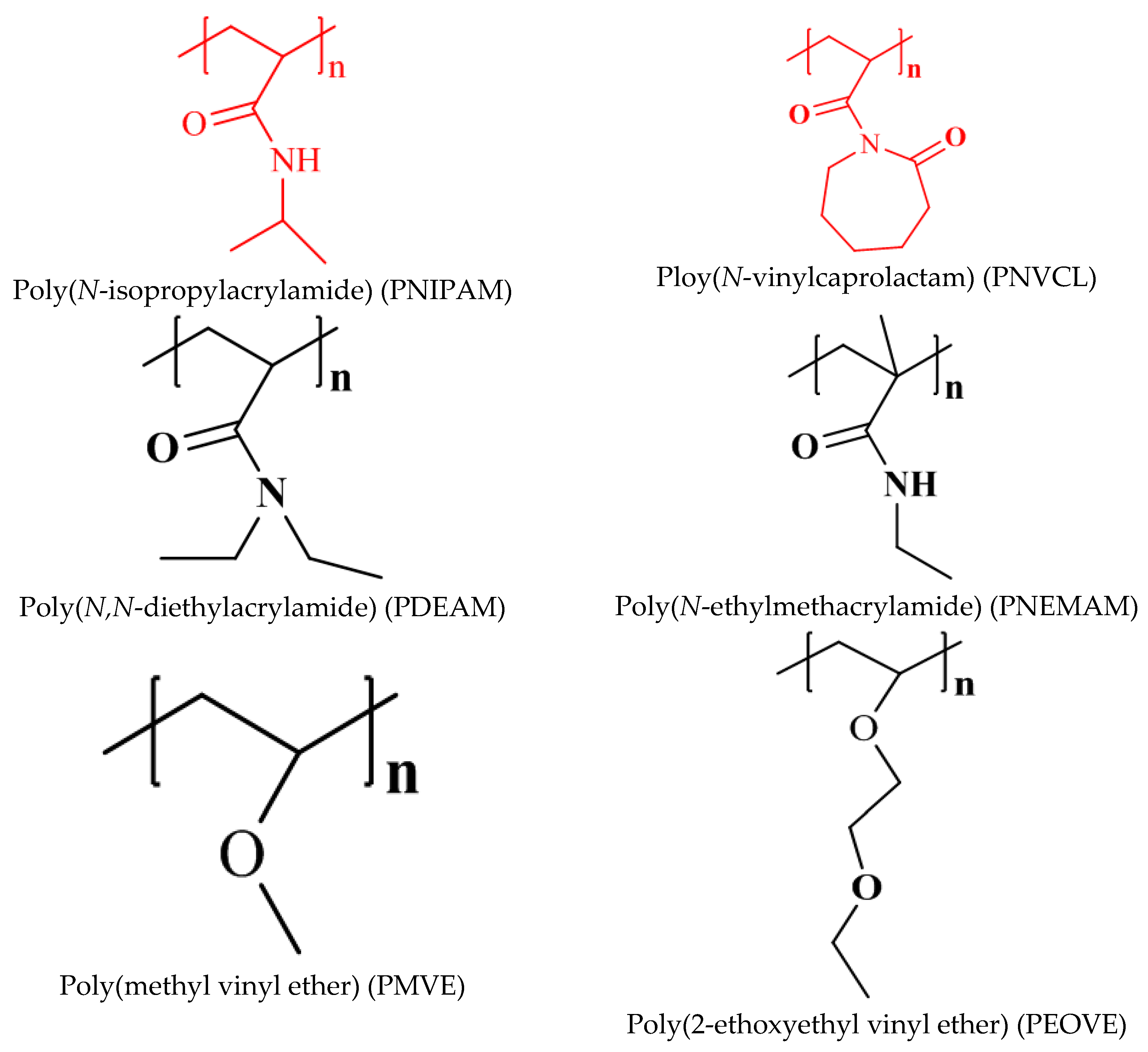

They are increasingly used in radiation curing systems because of a lower toxicity profile than the commonly used acrylic monomers.

They are also commonly known as acrylics or polyacrylates acrylate polymer is commonly used in cosmetics such as nail polish as an adhesive.

Reactions that lead to vinyl ethers can be divided into four groups.

Acrylate polymers are a group of polymers prepared from acrylate monomers.

Basf combines 90 years of experience in the development of high quality functional vinyl monomers including vinyl ethers and n vinyl compounds with state of the art know how and technology.

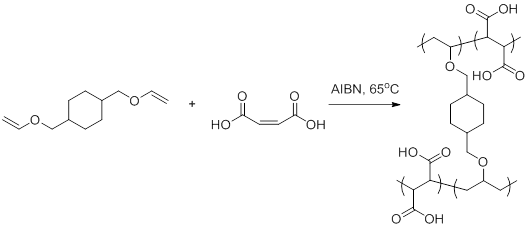

The results of polymerization and initiation experiments at 25 c show that the alternating copolymerization of maleic anhydride monomer 1 and ethyl vinyl ether monomer 2 is consistent with a.

Ii affording vinyl ethers as side products.

Cyclohexyl vinyl ether chve 2182 55 0.

These plastics are noted for their transparency resistance to breakage and elasticity.

Vinyl ethers undergo radical initiated copolymerization in the presence of specific monomers such as maleates fumarates and acrylics.

21 the vinyl ether transfer agents like other vinyl ethers generally show marked acid sensitivity and are not suited for use with acidic monomers e g acrylic acid aa methacrylic acid maa.

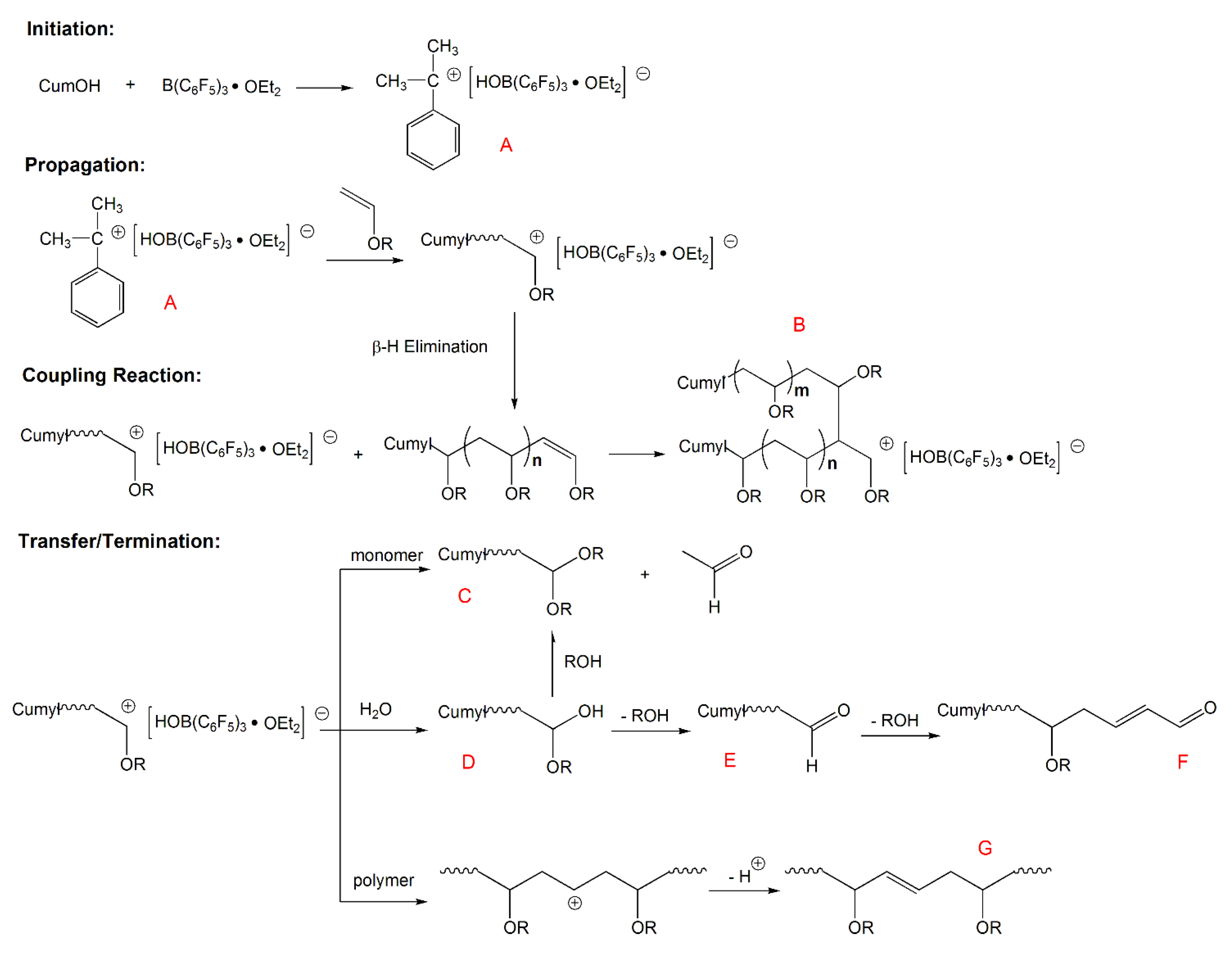

The polymers formed have a ketone end group e g 19 scheme 9 functionality can be introduced on z or r to modify reactivity or to tailor the end groups as in the examples 20 22.

Iv potentially upgradable for reasonable production of vinyl ether monomers.

Iii used in industry to produce vinyl ether monomers.

The name is also used for any compound containing that group namely r ch ch 2 where r is any other group of atoms.

Iso butyl vinyl ether ibve 109 53 5.

An industrially important example is vinyl chloride precursor to pvc a plastic.

With an ever expanding product portfolio basf can satisfy your needs for functional vinyl monomers now and in the future.

In chemistry vinyl or ethenyl abbreviated as vi is the functional group with the formula c h ch 2 it is the ethylene iupac ethene molecule h 2 c ch 2 with one fewer hydrogen atom.

Conventional web curable monomers are classified in radical curable monomers such as meth acrylates vinyl compounds and in cationic curable monomers such as vinylether epoxy and cycloaliphatic compounds.

Basf s global leadership in acetylene chemistry has made it the leader for development and production of functional vinyl monomers.