What is design pressure and how does it impact the windows or doors you are considering for your home.

Understanding ultimate and nominal design pressures for windows and doors.

Windows and sliding glass doors must meet the requirements of industry standards that include air water and structural testing.

Using this design pressure as a basic element architectural designs for building walls doors and windows are created accordingly.

A dp or design pressure rating is a numerical value given to a building component that represents its ability to withstand a given amount of wind load.

The pressure is caused by wind blowing on and around the subject property.

A higher dp value indicates a window or door that can withstand more wind water and or structural load than a window with a lower dp.

As defined by the aama american architectural manufacturers association wdma window and door manufacturers association and the nfrc national fenestration rating council design pressure is a rating that identifies the load induced by wind and or static snow that a product is rated to withstand in its end use application.

According to aama american architectural manufacturers association wdma window and door manufacturers association and the nafs north american fenestration standard design pressure dp is a rating that identifies the load.

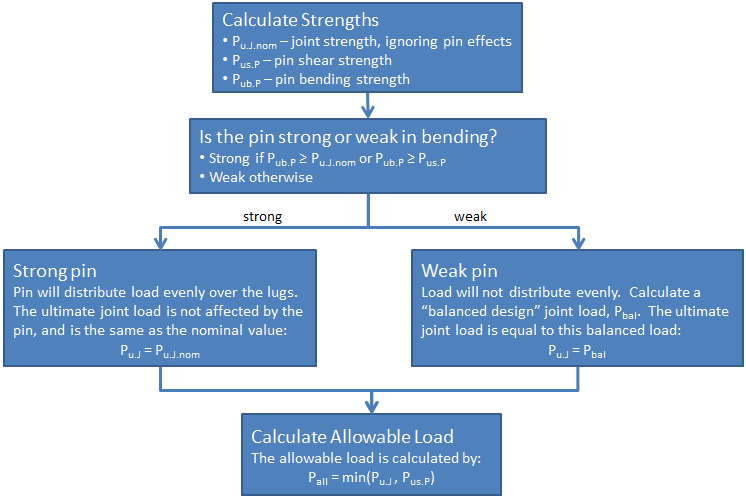

Dp ratings represent three performance elements structural load water resistance and air infiltration resistance.

Note also that for skylights the structural design pressure is 200 percent of design pressure whereas it is 150 percent for windows and doors.

Minimum design wind pressures the design wind pressure for c c shall not be less than a net pressure including internal pressures of 16 psf acting in either direction normal to the surface i e.

High speed wind such as wind during a hurricane creates positive and negative pressures and this pressure can tear out windows and doors break glass and force rain into your home.

Exterior windows and doors shall be designed to resist the design wind loads specified in table r301 2 2 adjusted for height and exposure per table r301 2 3.

What this means is that a lab has carefully tested a window s design pressure by measuring how many pounds of pressure per.

For testing required in sections r612 6 r612 7 and r612 8 design pressures determined from table r301 2 2 or asce 7 are permitted to be multiplied by 0 6.

The water penetration resistance test pressure for r products is also 15 of dp.

Let s start with the definition of design pressure.

Understanding design pressures are relatively simple.

Design pressure testing measures the performance of fenestration products to withstand positive and negative pressures.

As required by the florida building code every new window installed must meet a minimum design load pressure.

10 psf asd general requirements.

Design pressures are the amount of pressure put on the openings envelopes windows doors during a hurricane.

Dp stands for design pressure.

Combined together all these factors give a measure of design pressure which is the product of all these different pressures a building is exposed to.